I love having this day off, gives me time to reflect how lucky I am to live in such a great country, I have always loved living here and especially here in Southern California where the weather stays pretty constant and ideal for taking your motorcycle out and about. I have much to catch up […]

Tag Archives: 750 Honda

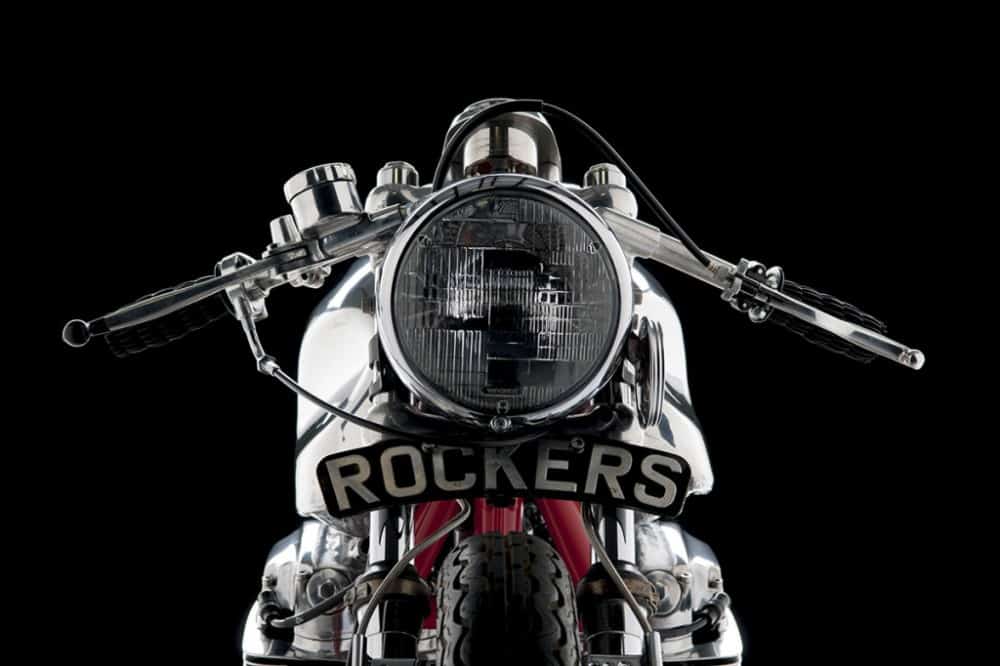

Time does indeed scream by at a pace that I really cannot fathom these days, but I am glad there are such things as you Tube etc that keep videos that I posted all them years ago. Here is the “Rocket Four” Bike that I created out of an old non running inline four, I […]

This is a rare “Sandcast” 1969 Honda CB750 “Sandcast” that’s historically significant for two reasons, firstly it was the world’s first “superbike” and secondly it was bought new by Steve McQueen through his production company Solar Productions. For those who may not know about this 500 pounds of Iconic Motorcycling Mastery, here is a small […]

Well, here we are, the weekend is almost upon us, things are still bad when it comes to Covid-19, this is a crazy time for us all, but- We have to live life and try and work the best that we can with what we have these days, and I hear from many Customers of […]

Many people have sent me their forks over the years to rebuild, polish or just hop up a bit as they get tired after 40 years of taking punishment from all road surfaces over time. As the photo shows above, this is the old set that I am going to be working with, I strip […]

I am not and never have been a fan of dead lines, but right now I do have one in hand, March 23rd, thats when the OG show Custom Show is on and somehow I have to strip the Brat bike I built and hopefully finish it in time for the show. No easy task […]

This is the Old Russ Collins Bike I created from parts. Below is a Video but hard to hear as the old Powder coating shop behind us is loud as hell, but it was a tight motor and loved to ride it, hard to hear but this is the only video I have of it. […]