Wow- hard to believe that I have been selling these systems for over 18 years now and still going strong, so this time I thought that I would offer a new Ceramic Coating Color, as many people ask me about these things. So what I now offer is the New Titanium Coating and it looks […]

Tag Archives: four cylinder

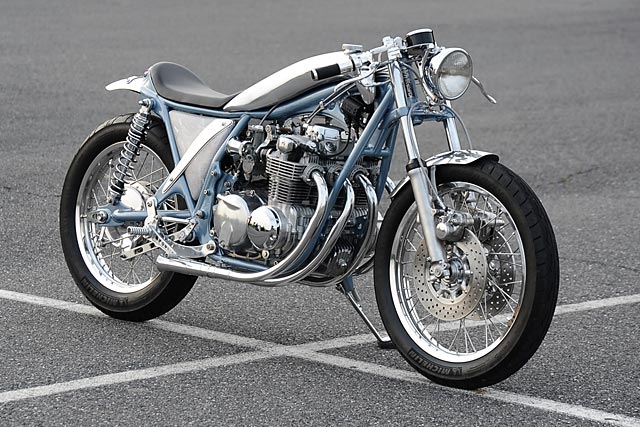

Some times there is a Cool Motorcycle that has been redesigned and contoured into something of beauty, and if seen, would make you stop in your tracks, I have seen many creations made here and over sea’s and when I saw this CB500, you had no choice but stop and admire the countless hours of […]