This is a rare “Sandcast” 1969 Honda CB750 “Sandcast” that’s historically significant for two reasons, firstly it was the world’s first “superbike” and secondly it was bought new by Steve McQueen through his production company Solar Productions. For those who may not know about this 500 pounds of Iconic Motorcycling Mastery, here is a small […]

Tag Archives: sandcast

Not always you see too many Sandast’s these day, I’ve owned about 9 over the years and sold many parts for them back in about 2003 but harder to locate for sure these days- So, when you see a Cafe Racer creation that was built in 1969 and sent to Sweden, then it is quite a […]

Shop by category Enter your search keyword ANY ONE GOT $130K laying about? Have one to sell? Sell it yourself Details about 1969 Honda CB 1969 HONDA SANDCAST CB750 CB 750 VERY RARE PROTOTYPE Well, this is a super rare cb750 and […]

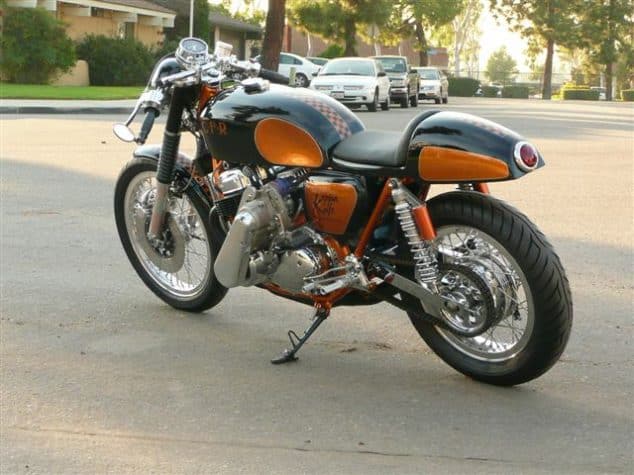

KOPPA KAFE MY WILDEST RIDE. Here is a Video I have done to show the build. Enjoy: Hey Gang OK, here we go, I miss my Vincent Cafe, I must build something Cooler! COOLER? How can that ever be achieved? I know, a big task is ahead of me but hear me out. How about […]