No products in the cart.

FOUNDRY’S LATEST KAWASAKI Z650 CAFÉ RACER

05

Feb

Tom Simpson | Owner | Designer | Builder | Barista !

Tom was a blacksmith with an interest in motorcycles that stretched back to when he grass-tracked on mopeds around a field.

“The seed of my bike obsession took hold when my dad brought home a knackered Suzuki GT250 Ram Air,” he says. He’d been given it as part payment for some work but couldn’t get it going so after a lot of pestering it was given to me. My uncle and I got it to start, but a stripdown found a bent con-rod.

“That was it for that bike but I was hooked. Smoking around on a mate’s GS500 was the precursor to my first big bike, a Hornet 600. Then, when I was into my blacksmith work fulltime, I was also riding, welding hardtails, making occasional bits and gradually it progressed into full time work.”

What makes Foundry Motorcycle machinery stand out is Tom’s philosophy to incorporate new ideas with every build. “By not formalising what I do it means that it keeps everything fresh. I love coming to work and I try to build different things.”

But how does Tom define his style? “I think my smithy background comes through. It’s more organic rather than bolt-on. Most of the stuff on my bikes I make right here. I always make the exhausts flow in a particular way. I make all my own subframes. If I keep building the same over and over I could make more money but each time I try to do something, it’s different.”

So here we go with a classic style Z650 creation that Tom had to use his Blacksmithing skill set to accomplish the really bitchin set of wheels that adorns the tarmac of the British Countryside.

The Customer dropped a frame, wheels, tank and a set of forks to the Chichester based workshop that’s located about 14 miles North West of Bognor Regis and 22 miles East of Portsmouth in the UK.

Unfortunately there was no powerplant as the Client was working the the motor himself, but luckily Tom had a empty shell of an engine from a previous build and was fortunate to be able to use that as a fixture until such time as he could fit the rebuilt item- But, that does not stop Tom and his fabricating mind in creating something that he and his client had talked about and working from a few sketches that Tom had laid out whilst in Conversation with the customer to what he was looking for.

As Tom’s previous trade was of a Blacksmith, he was used to swinging a Hammer and manipulated metals to form into what he was imagining, and this was a similar task to Blacksmithing, being that he has to heat and bend, cut weld and grind the frame to create something unique and of course rideable.

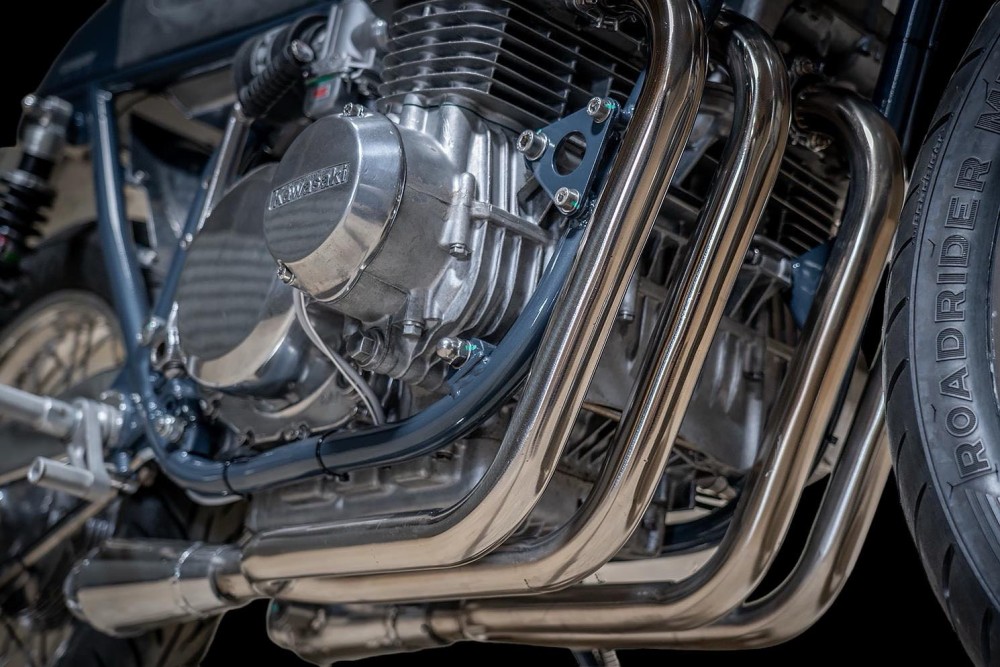

The Customer has informed him that he did want some dramatic changes which meant Tom would have to fabricate a custom swingarm, an entirely new subframe, and a full stainless steel exhaust system, something that was not an easy task and if it was, well, everyone would do it right?

As you can see, a lot of time and skill was used to fabricate the Aluminum swing arm and the end result is a Factory race looking set up thats been highly polished to a chrome finish, along with a set of YSS shocks and Tarrarozi styled rear sets for that Cafe Racer look, of course Aluminum rims polished and Laced to polished stainless spokes was the best way to go for that 1960’s North Circular look.

I personally have built a few swing arms in my time and can see the amount of time and energy that went into making this particular version work and look almost factory.

Moving to the subframe, Tom decided to avoid the typical cut-‘n’-loop style that so many of recently built Racers and Brat style bikes adorn- Instead, he designed a tail hump that would integrate neatly with the rear frame rails. A set of custom brackets and bosses ensures that everything fits together very neatly and has form and function rather than the normal “Cut n Shut” style.

The tail section’s bodywork is divided into a couple of sections. The traditional racer hump forms the top half, while the bottom serves to blank off the underside of the tail, while also acting as an electronics tray. The overall effect is very uniform and flows so well and not bulky.

Hand fabbed mini Mega’s finish of the exhaust headers and are polished too, these bark like a Police dog at a Football match and make sure people know the client is there, I also belive in loud pipes and like the way they are aesthetically laid out.

CR carbs were the order of the day and with foam filters these units fill the void that many leave when they remove the stock airbox, A Lithium-ion battery now hides under the tail bump, with a Motogadget mo.unit control box stashed under the seat, makes everything very neat and tidy, Tom wanted to keep the Stock petrol tank as it has the right lines to flow with the rest of the bodywork. The Gas Cap is a Monza style piece to keep in with that Ton Up society and the tank is fitted with a Click Slick petcock from Golan to make sure it delivers the go go juice .

Up front you will notice that Tom added another Bacon slicer to the refurbished front forks and of course all the aluminum is polished to a chrome finish, and the client requested not to have a front mudguard, but Tom had the presence of mind to leave the factory mounting holes in place incase he gets fed up of road grime in the face and he han easily add a fender. Also the Nostalgic Avon Roadrunner tires were fitted to make sure this Z650 sticks to the tarmac.

Everything is nice and tight and regularly ridden in the English countryside and these hand made exhaust bellow out to warn whos coming around the next bend.

The only jobs that happened outside of Foundry’s workshop—other than the engine build—were the paint and upholstery. S.Jago Designs laid down the stylish paint job, and Trim Deluxe added a touch of class to the seat. But the rest is all Foundry and you can tell, as the Devil is in the detail and this has it with a Capital D.

Sitting pretty with a great stance, this machine looks and sounds the part and am sure the Client is over the moon with the way this turned out, considering this was a design on a scrap of paper.

So if you ever get to Blighty, drop into Foundry and see what Tom is creating, I am sure it will raise both eyebrows when you walk into the shop?

Nice Job Tom, well done fella.