Well, this Labor day weekend has been Hotter than a bowl of Chilli peppers, right now, as I type this, its 108 Degree’s. Now, I have a lot to do in the garage and I need to move some parts that have been sat in storage for a long time, I looked at what parts […]

Tag Archives: custom

Well, it is still hot as hell here in southern California, and I have been flat out with work, so not too much time on the Blog side this time but always try to post something to show you guys n gals out there. I have a few bits and bobs laying around in my […]

CORONA DIARIES 2020 from the deep warm depths of La Mirada. California August is now out the window, on its toes and halfway down the road, thanking god that his part of 2020 is now in the can and hopefully the next time August comes around, we might be able to life a more normal […]

A Super Hot Weekend, why do I attempt such crazy work when the weather is like this? I guess we all do right? A long day but managed to get the old carbs out as the idle was not functioning, but a complete redo was needed and boy what a pain in the arse the […]

Hey you lot, hope things are OK with everyone? And you are trying to get on with your Motorcycle Project in this Pandemic. I am still flat out playing catch up and thats a good thing to be busy. With the weekend crashing by so fast, its hard to sometimes catch up on a daily […]

Its that time at last, Friday evening, its nice to know that the weekend is now here, I have many orders to try and get out the door and tomorrow I shall be up early so i can pack a bunch more orders to send to my Customers. It’s my Birthday Monday and although i […]

The time is flying her in Southern California, I am so busy right now, mostly with exhausts and making other parts for our beloved Machines, etc and I really appreciate you supporting me in these times that we are in right now.Volume is a little quiet but just wanted to say hello to ALL you […]

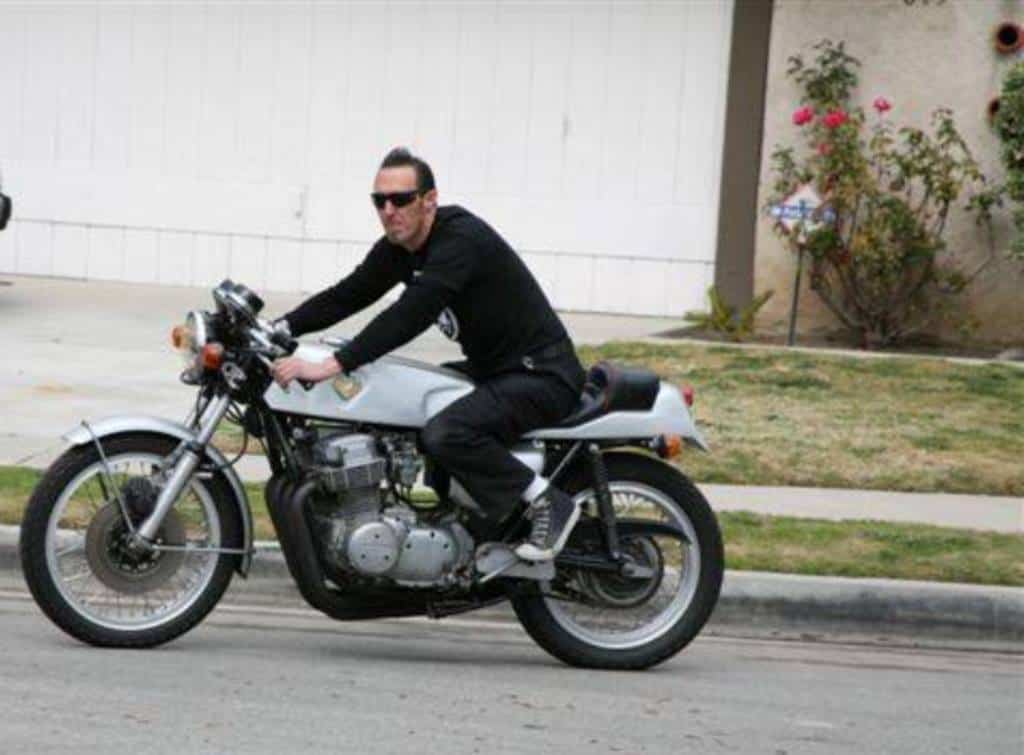

Wow! Where does the time go these days? I literally forgot about building this bike and found some tiny photos someone took of me, so thought I would try and show them on here, so you can see this Classic machine once again. Fun times when I lived in the City Of Orange, where I […]

Well, with everything going on right now, I need a little pick me up and a little while ago I was invited as a long term Builder to exhibit a Motorcycle I am building from scratch, to display at the Buffalo Chip at Sturgis this year- but, with the Pandemic, everyone was held up in […]

Having a day to remember this afternoon, remembering my 2013 Triumph Thruxton that I bought as stock as the Proverbial Rock in Brea and then set about changing a few things as I went along and get it to the style and menacing Gnarly Growl of the mufflers as I hit the apex of a […]