I have been a fan of F1 Formula race cars since I was a teenager, regularly watching the races on our 3 channel television, I loved watching these guys in the JPS Renault Lotus and my First Motorcycle that adorned the Motorcycle world was based on Emerson Fittipaldi’s Black and Gold F1. Now, over half […]

Tag Archives: Home made

It’s a funny old world, I mean, I initially went out to get a pint of milk and on the way there I came across a stash of SOHC Motors that a buddy of mine needed to off load as he was clearing his place out for renovations etc, what better way of getting rid […]

Well, it is still hot as hell here in southern California, and I have been flat out with work, so not too much time on the Blog side this time but always try to post something to show you guys n gals out there. I have a few bits and bobs laying around in my […]

Well today’s blog is cool as I consider this builder as a friend of mine, DownShift Studio is run by Jeremy Lacy, an industrial designer based in Denver who specializes in illustrations and sketches of custom bikes, often helping fabricators and builders from around the world visualize their ideas and projects before the metal is […]

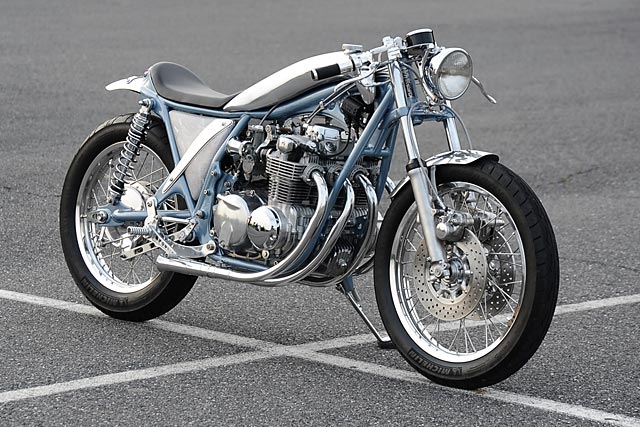

Some times there is a Cool Motorcycle that has been redesigned and contoured into something of beauty, and if seen, would make you stop in your tracks, I have seen many creations made here and over sea’s and when I saw this CB500, you had no choice but stop and admire the countless hours of […]