If a bike like this can’t get your heart beating faster I don’t know what will. You don’t even have to be into race or vintage bikes to appreciate the attention to detail and engineering excellence here. We use the term “engineering art” with Bimota alot but this Yosh/Honda just stepped up to the top of the podium as […]

Tag Archives: yoshimura

I have always loved creating My style of machine for Customers and this one is no exception, the KC Special turned out to be a great looking ride and the Owner Keith Conrad ( Hence K.C.) lives in Milwaukee and asked if I could revamp his old 1975 CB750 into a Silver and Black Cafe […]

Well, what a bloody tough year we have all had, for me it has been crazy, what with moving to another location as well as catching Covid and then on Christmas day catching an awful cold with the same symptoms of Covid but without the temperatures, its been a long battle throughout. From having some […]

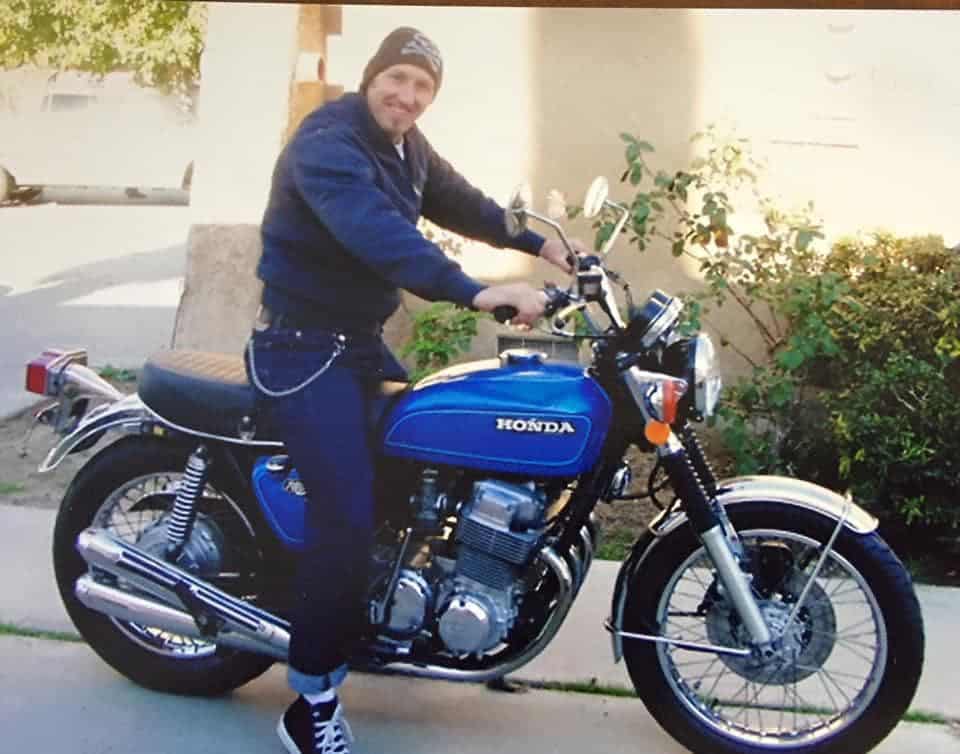

I forget to add pics of Motorcycles that I have built over the years and some times I kick my self for not posting anything, but today I will overcome my forgetfulness and add some photos of a fun creation I built using parts that I had around the shop. I wanted to build […]

No idea where the time has gone to be honest, but I always loved creating this machine, just because it has so many great Original parts on it that really did make people turn heads. So I started off with a bunch of parts and already had the idea of how I wanted this, as […]

Hey Everyone Hope that you are all well and trying to continue doing what you enjoy- This Pandemic is a royal Pain in the proverbial arse, but we have to stay strong and continue masking up, keeping your distance and soon after we all get the Jab, hopefully we can get to some sort of […]

Well, 2020 can go and bugger right off, what a shitty year for everybody around the world, and we still have some ways to go before we can all meet up anywhere, so I tend to think I shall be here at home and will put my time and energy into making New parts available […]

A couple of days left in this terrible Pandemic year, good riddens to it and sure hope that 2021 will be great for us all, of course it will take probably half of that year for all of us to get back on an even keel so to speak, but we shall get there and […]

Well, a day off at last, albeit I will be catching up on things at home etc, but- I am in my office and for once, it has started to rain. Something that we do not get much of in Southern California, so I will engulf this as it reminds me of back home in […]

Time does indeed fly by and as we now spend a lot of time at home, I thought that I would let you know that what ever I do, there will always be time to turn wrenches and create parts or a cool Custom machine in my workshop, and I continue to do so, next […]