My Exhausts System named the Sidewinder is a Fun and Easy to fit 4 into 1 Performance system that will fit all CB750-CB550 and CB500 Four Honda Machines. I am super proud of all my systems and this one I like because it allows for you to use your main stand if you so wish, […]

Tag Archives: cb550

Some of you may know that we have had a Barn built now for my New workshop, and as you know, materials for building have literally gone through the roof- So I thought that whilst we are refurbishing the California Ranch house, I will try and repurpose some of the timber that we ripped out […]

Well, for 22 years I have been sending my very own 4 into 1 exhaust systems to Customers all over the globe and along the way I have many repeat customers. I love hearing from them too, as they perform really well throughout the power curve and sound so cool when you get on the […]

I know, I know- I should not complain about the weather, but- I left the shores of Blighty back in 1997, this weekend it will be in the 90’s and I am lucky that I now have the Barn to work in, albeit no A/C. Its surprising how much you can get done when there […]

The New Year is here, still a crazy world out there and I am not taking any risks to get ill again, I got all my shots, I then caught Covid and then at Christmas got a cold almost as bad as the New Omicron, what a shit start to the year for sure, but- […]

Here we are 2022 at last, man – What a crappy 2020 and glad to see the back of it and start a fresh and hope that we all have some good health and enjoy life as much as we can. I somehow caught the Flu over Christmas and it Royaly buggered me up, Only […]

No matter what is going on in the world, one thing remands the same, and that is the ticking Clock, she will always continue to grind away 24-7 and I am vert aware at times of that as deadlines come up real fast when yo are a small business, but, there is nothing better than […]

Well Howdy Everyone Hard to believe that almost 22 years ago I started making parts available for these and other machines and continue to do so today, I try and help everybody out where I can, and I really do enjoy what I do for a living. None of these parts are made in China […]

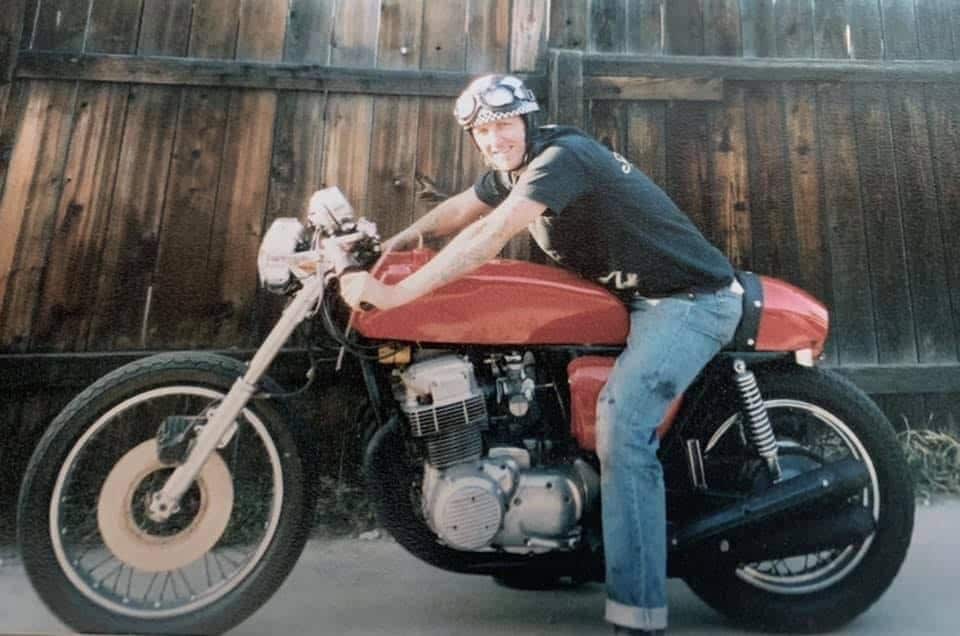

With all this Crazy Mayhem with the virus and wear a mask etc., its nice for me to be able to just do my own thing out in the sticks and away from the craziness that has really changed the Globe right now, but I came across this photo of me many years ago when […]

I get so many emails asking about certain things that I create on the bikes and parts that I build here at my place, so- I thought I would do a little Blog on my Custom Fork service that I have been doing for many years and shipping these set ups all over the Globe. […]