It’s a funny old world, I mean, I initially went out to get a pint of milk and on the way there I came across a stash of SOHC Motors that a buddy of mine needed to off load as he was clearing his place out for renovations etc, what better way of getting rid […]

Tag Archives: cb750a

Time does not stand still and I now have all sorts of work to do but glad that I still get many emails, Phone Calls and of course texts, asking about builds, parts, service or idea’s etc, I love what I do and even though I really have had not had the time to build […]

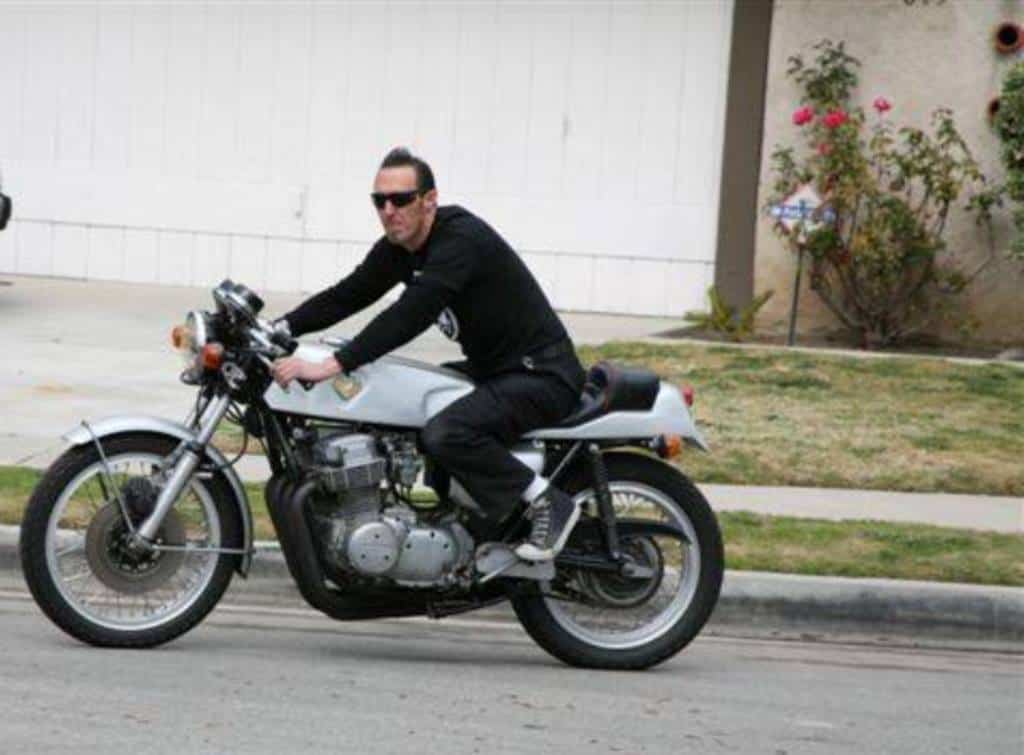

Wow! Where does the time go these days? I literally forgot about building this bike and found some tiny photos someone took of me, so thought I would try and show them on here, so you can see this Classic machine once again. Fun times when I lived in the City Of Orange, where I […]

Well, the Rains are here again tomorrow, so had to tear into many projects to try and get ahead of the storm, as it will restrict me to many things I need to do to create this Custom Motorcycle, the Exhaust I originally tried out was pretty Bad Arse- But I wanted something really trick, […]

Well, the weather has been fighting me this month, worse Month since 1962 for the amount of H2O we have received and again today as we head to the end of February, we have more Rain coming down this week, so I need to try and use my time wisely and get as much done […]

Wow- hard to believe that I have been selling these systems for over 18 years now and still going strong, so this time I thought that I would offer a new Ceramic Coating Color, as many people ask me about these things. So what I now offer is the New Titanium Coating and it looks […]

Well, here we are with the Harlequin Honda that I have created, its been a long build as originally the Motorcycle was bought down from Washington on November 4th 2015, Edwin Cooper was not well, he had Cancer and wanted to try and revamp his trusty old Steed that he had had for many years, […]

Many emails over the years ask about electrical issues on their Honda’s, I thought that today I would try and add some information on here today to try and help you out a little. The vintage bikes from the 1970’s, such as the HONDA CB550, have a simple electrical system consisting of approximately 40 components […]

Well, Christmas has gone and today for me is known as Boxing Day, a tradition that goes back further than the invention of the inline Four Honda, and today as I sit at home and reflect on the last 12 months, I thought that I would type up a blog on the good old CB750 […]

Over the years I have built a number of inline Four machines as you may well know, I have always liked these Motorcycles because I used them as a Courier Bike back in the UK, they were Affordable and reliable and lastly they were an awesome Platform to be able to adapt to how you […]