2022 Isle of Man TT began on Sunday May 29 and ends on Friday June 10. mow, there will be many close calls and unfortunately sometimes riders who have crashes at such fast speed either end up in Hospital and sometimes the Morgue, that’s why this is one of the worlds most grueling Motorcycles […]

Tag Archives: classic

Well, for 22 years I have been sending my very own 4 into 1 exhaust systems to Customers all over the globe and along the way I have many repeat customers. I love hearing from them too, as they perform really well throughout the power curve and sound so cool when you get on the […]

Well, time and tide wait for no man, woman or child for that matter, I have been flat out as of late and will be busy for some time to come for sure, albeit in the Barn designing a few different exhausts and parts etc. Fun times ahead and I hope to try a few […]

I am always impressed by machines that are created down under, I was lucky enough to Live in Victoria and in New South Wales for 4 years and their passion for anything with two or four wheels is breathtaking at times. Here is a write up pipeburn came up with I wanted top share with […]

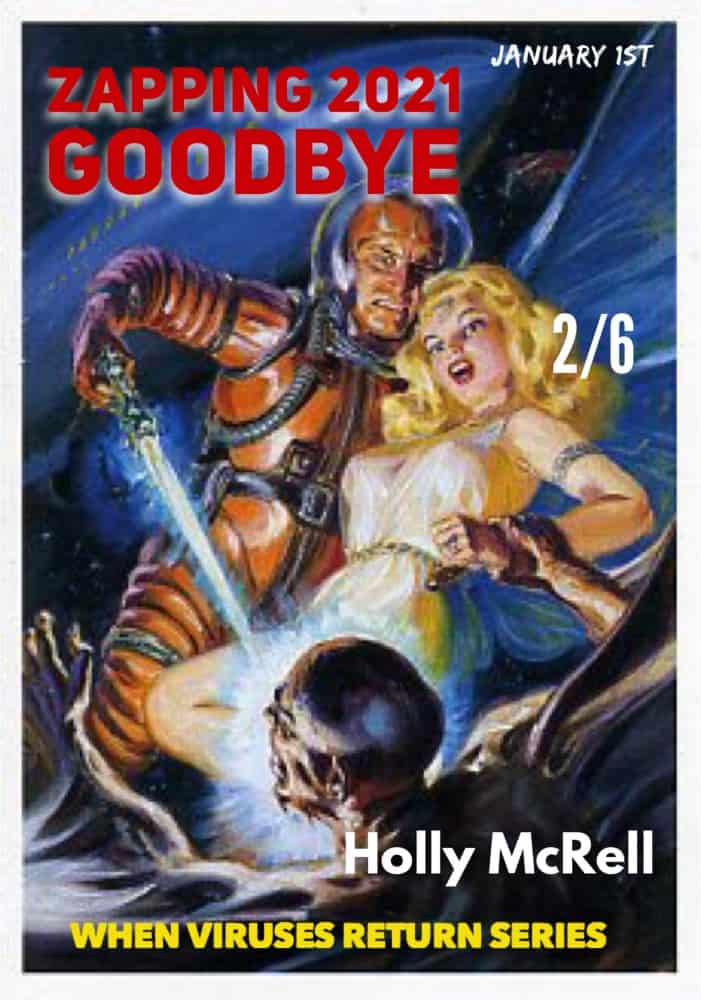

The New Year is here, still a crazy world out there and I am not taking any risks to get ill again, I got all my shots, I then caught Covid and then at Christmas got a cold almost as bad as the New Omicron, what a shit start to the year for sure, but- […]

Here we are 2022 at last, man – What a crappy 2020 and glad to see the back of it and start a fresh and hope that we all have some good health and enjoy life as much as we can. I somehow caught the Flu over Christmas and it Royaly buggered me up, Only […]

Well, what a bloody tough year we have all had, for me it has been crazy, what with moving to another location as well as catching Covid and then on Christmas day catching an awful cold with the same symptoms of Covid but without the temperatures, its been a long battle throughout. From having some […]

I forget to add pics of Motorcycles that I have built over the years and some times I kick my self for not posting anything, but today I will overcome my forgetfulness and add some photos of a fun creation I built using parts that I had around the shop. I wanted to build […]

No matter what is going on in the world, one thing remands the same, and that is the ticking Clock, she will always continue to grind away 24-7 and I am vert aware at times of that as deadlines come up real fast when yo are a small business, but, there is nothing better than […]

Well Howdy Everyone Hard to believe that almost 22 years ago I started making parts available for these and other machines and continue to do so today, I try and help everybody out where I can, and I really do enjoy what I do for a living. None of these parts are made in China […]