I have just completed another machine here at the Barn and of course, it’s a CB750 Honda, but this time an old 1975 F model that I had in pieces in boxes that were in the barn and some parts were outside, Just trying to use up parts that I have accumulated over the years […]

Tag Archives: rear sets

I have been a fan of F1 Formula race cars since I was a teenager, regularly watching the races on our 3 channel television, I loved watching these guys in the JPS Renault Lotus and my First Motorcycle that adorned the Motorcycle world was based on Emerson Fittipaldi’s Black and Gold F1. Now, over half […]

Hey Everyone, well its the weekend, I have been a bit ill in health recently and have not been on the website as much as I would like to but I am back on my feet, few health issues to try and figure with the Human Technician but I am sure I will get that all […]

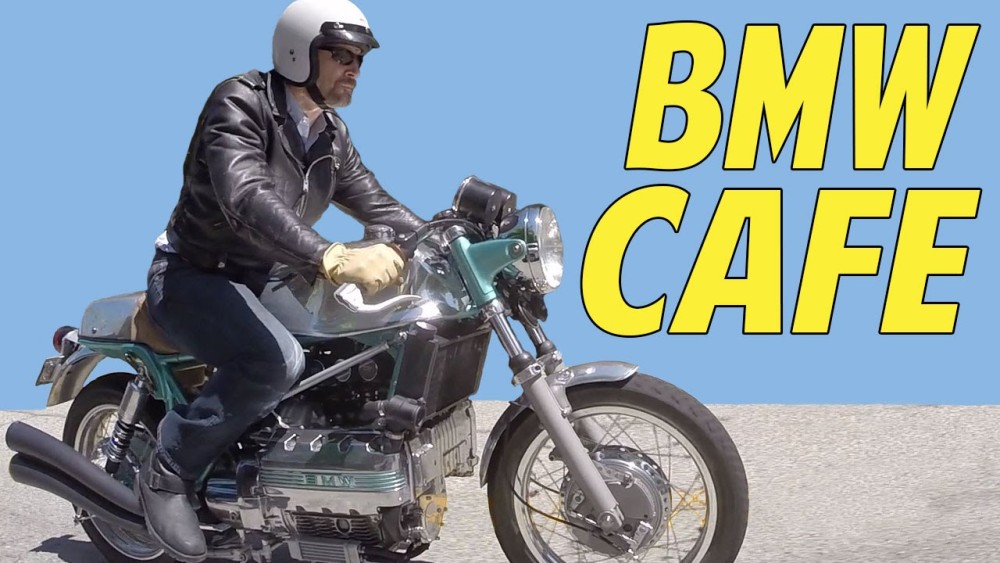

Boy the weather is changing here and its getting a little cold in the Mornings, but I still sling my leg over my steed and ride off to work, but I actually put bubblewrap inside my jacket to keep the cold air out of my chest, an old Motorcycle Courier trick in London that I […]

Well, time and tide wait for no man, woman or child for that matter, I have been flat out as of late and will be busy for some time to come for sure, albeit in the Barn designing a few different exhausts and parts etc. Fun times ahead and I hope to try a few […]

I forget to add pics of Motorcycles that I have built over the years and some times I kick my self for not posting anything, but today I will overcome my forgetfulness and add some photos of a fun creation I built using parts that I had around the shop. I wanted to build […]

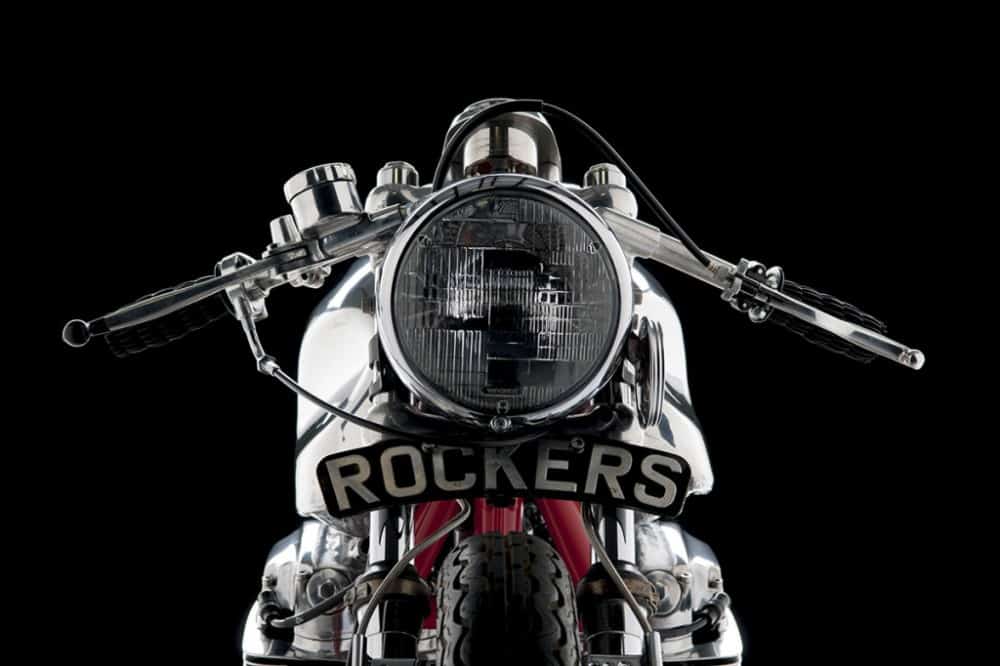

No idea where the time has gone to be honest, but I always loved creating this machine, just because it has so many great Original parts on it that really did make people turn heads. So I started off with a bunch of parts and already had the idea of how I wanted this, as […]

Well, here we are, the weekend is almost upon us, things are still bad when it comes to Covid-19, this is a crazy time for us all, but- We have to live life and try and work the best that we can with what we have these days, and I hear from many Customers of […]

Happy Tuesday Everyone Fast approaching the 18 year Milestone here at Carpy’s Cafe Racers and have always enjoyed what I do here in Sunny California, and today is another great day and seeing as its Blog Tuesday, just wanted to than you all for purchasing from me and all the great emails and phone […]

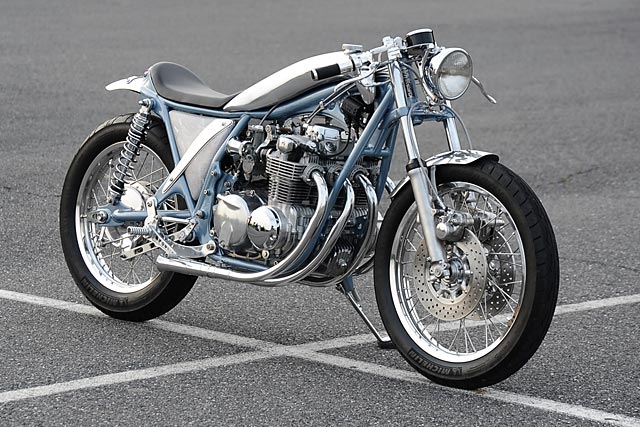

Some times there is a Cool Motorcycle that has been redesigned and contoured into something of beauty, and if seen, would make you stop in your tracks, I have seen many creations made here and over sea’s and when I saw this CB500, you had no choice but stop and admire the countless hours of […]

- 1

- 2